Where is your product’s future?

If this year in 2021 you’re designing flashing wrist bands for the FIFA World Cup in 2022, then it’s unlikely you’ll be worried about your product’s next ‘development stage’ in 2023. Should you be building a house you’d expect greater longevity. You’d hope the architect had designed it to still be standing in 2039, but you would not have expected them to design elements of your house to provide facilities for you to easily add an extension. If you’re designing a router, it’s unlikely that the product will still be in use in 2027, but it is likely that an iteration of your current design will be shipping to your customers. If you are creating a factory, its likely that decisions you make now will affect how flexible your production line is and how able it is to cope with future developments.

Longevity or Variant Flexibility

There is a difference between designing for a product or product line that needs to last into the future and one that needs to provide a base for a number of variants. They are not mutually exclusive but both have an impact on the effort and cost. Without being mindful of the intended product route, it is not possible to plan for this flexibility. Longevity can also be divided into product longevity and design longevity, both of which can affect your product’s end date.

Flexibility

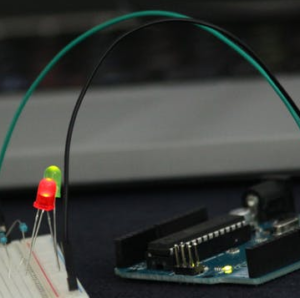

Considering the examples above, if you are creating the flashing wristband and know that you need red, and yellow variants. That’s what the organisers have asked for, a different colour for the opposing teams. It is also possible, but not yet confirmed, that you’ll need green, orange, and blue variants for the semi and finals, but this is only being ‘talked about’. It would be short-sighted ordering your integrated chip-on-board circuit with a ‘built in drive resistor’ to provide the 1.8v needed for the LEDs; only to find the green and blue models can not be made.

It would be much better to add a requirement to allow this flexibility by designing the current regulating resistor as a separate component allowing the 3.2v needed for the other colours. This is a flexible design variant, it is known about and has a high probability of being needed. The impact of this on the design is minimal. The cost saving; allowing many different bands to be produced with the same chip-on-board IC; far outweighs the cost of the extra pick and place operation to add the separate resistor.

It would, however, be very unlikely that producing a variant that could be connected to a sounder to ‘beep’, as well as flash would be produced. Just imagine how annoying the stadium would be filled with beeping noises. The extra cost of designing the chip to have that facility would not produce pay back. That said, if your company produces other novelties; which include a kids toy that needs flashing and beeping; then you may be able to justify using the same chip design across two product ranges.

In house building, the variants are likely to be 2, 3 and 4 bedrooms or left and right hand versions of semi-detached, properties. The commonalities providing cost benefits, when ordering anything from windows to staircases.

Design Longevity

Whilst we expect the house to be still standing, and the factory to still be producing; we’d not be overly surprised if the router had stopped working.

The house design is essentially static. It does not change, unless the architect is commissioned to oversee new builds. In that case they may need to be altered to meet changing building regulations.

The concepts of the router should still be good; there should be aspects of our original design in any current products.

The factory product may well alter, if it’s set up to assemble routers that are around 200mm long by 150mm wide; it would be very short-sighted to design all the conveyors and packing systems to only handle that one size. As soon as the new router design of 150mm by 100mm is required, the whole line would need to be changed. So designing for longevity; making as many of the elements of the system configurable or generic as possible; will allow you to accommodate future variants, even if their details are not yet known. Again a balance needs to be struck; designing the conveyors and packing systems that ‘might need’ to handle 3000mm wide packages, would plainly be overkill.

Product Longevity

Our house design could be thrown away after the estate is complete. It may not be possible to keep building the same type of house for twenty years. The product, does however need to be designed to last that long. The system requirements must specify materials which will last, no one would seriously want a house built of straw. Just ask the three little pigs… The products we make on the factory line will have their own longevity, this should have been specified at concept. Some elements of the factory may still be the same. It’s the overall design and operation that we needed to last, not necessarily the products being made. If we’d been assembling the wristbands, by now they will hopefully have been recycled, else they clutter in the attic of our house with not a flash left to give.

A Balance

We should not consider longevity and flexibility separately. Take the router itself; designing the board to allow the flexibility of adding support for a USB device to future variants is good planning. Adding a spare memory socket to allow more caching, to assist with the expected line speed increase with a switch to FTTP is prudent. Designing software and board layouts to cope with an experimental processor and protocols; that only exist in a university study; are likely to be a waste of effort given the expected lifecycle. Designing the software that could still be in use[*] or the basis of the router you will release in 2030, to cope with dates beyond 2038[**] is likely to be worthwhile!

Tool Support

Ensure your design tool allows you to collate, process, link and trace your variants and plan for longevity. Whether this is via an inbuilt mechanism, such as Cradle variants, or by linking longevity requirements as separate items to your main system requirements.

*Extremetech.com:Microsoft Windows XP Is Finally Dead, Nearly 18 Years Post-Launch Last official variant (Windows Embedded POSReady 2009) support dropped.

**Wikipedia:Year 2038 problem Seconds since 1970 32 bit integer seconds overflow